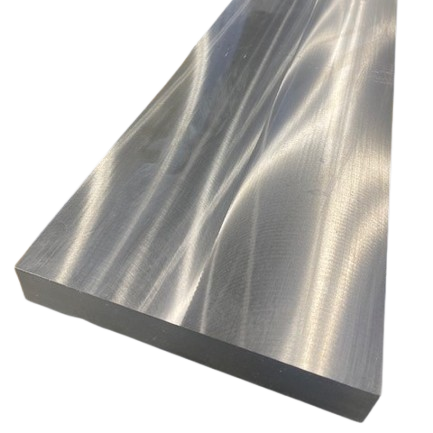

Molybdenum Hafnium Carbide Alloy

Molybdenum Hafnium Carbide (MHC) Alloy is a molybdenum-based alloy, that contains hafnium and carbon for superior forging performance. As a particle-reinforced alloy, the carbon is uniformly distributed along the alloy structure, giving it exceptional creep resistance and hot strength properties at extremely high temperatures. Additionally, this high-performance alloy is able to function under extreme mechanical and thermal loads. Elmet Technologies manufactures MHC alloy through a powder metallurgy process.

Some of the advantages include high thermal stability, no cold brittleness, dimensional stability, great hot ductility, optimum non-deformability, and very high crystallization temperatures. Although it can be somewhat challenging to machine, MHC alloy is best suited for machining processes such as drilling, lathing, and grinding. Isothermal forging dies made from molybdenum-based alloys like MHC offer high temperature strength and creep resistance, resulting in extremely accurate and very efficient die forging.

MHC: Molybdenum Hafnium Carbide Alloy

Elmet Technologies’ MHC is an established molybdenum alloy containing hafnium carbide, which is consolidated by the powder metallurgy process. The high recrystallization temperature, high strength, low thermal expansion, and high thermal conductivity of this alloy make it ideally suited for die applications. We also have the capability to customize our alloys to meet your requirements.

MHC: Material Characteristics

Maximum Product Dimensions

| Pressed and Sintered Billet | 29 in. (74 cm) DIA /10,000 lbs. (4,536 kg) |

| Forged Blank | 55 in. (140 cm) DIA |

Minimum Density (based on 10.2 g/cc)

| Pressed and Sintered Billet | 94% |

| Forged Blank | >99.5% |

For custom project requirements, contact Elmet to discuss additional material properties.

MHC ALLOY Advantages

- Great hot ductility

- No cold brittleness

- Dimensional stability

- High thermal stability

- Optimum non-deformability

MHC Alloy: Common Applications

Molybdenum Hafnium Carbide Alloy is an alternative to pure molybdenum (Mo) or TZM alloy. Its properties improve the performance characteristics of pure Mo, particularly in high-temperature or high-stress environments. MHC alloy is often the material of choice for the production of forging dies and fabrication of critical aerospace and defense components, such as blades, discs, rings, and hubs.

A Leading Manufacturer Of MHC Alloy

As a leading manufacturer of MHC alloy, Elmet Technologies has a dedicated team that provides extensive technical support for advanced materials. With U.S.-based manufacturing, our approach is simple. We offer each partner a unique customer experience that centers around better quality control, continued customer success, and direct access to our team with product traceability.