Molybdenum Alloys

Molybdenum alloys offer a unique combination of improved hardenability and high temperature strength for advanced forging applications. In hot metalworking applications, dies and tooling must resist stress, friction, wear, fatigue, and creep. This is where molybdenum alloys excel, delivering superior performance and longevity under extreme thermal and mechanical conditions.

Two notable alloys, TZM and MHC, are specialty materials for extreme conditions. These two materials provide superior strength, performance, and temperature resilience. In addition to pure molybdenum, TZM, and MHC, Elmet Technologies manufactures several other materials tailored to specific customer requirements, offering enhanced properties for demanding applications.

A Global Leader in Molybdenum Alloys

As a leading global provider of molybdenum alloys for unique application requirements, Elmet Technologies offers fully integrated manufacturing to control and tailor material properties like ductility, tensile strength, hardness, grain size, and more to meet demanding specifications.

High-Performance Forging Materials

Our high-performance forging materials are manufactured with exceptional powder metallurgy and refractory metal processing expertise, resulting in superior quality molybdenum alloys. We regularly partner with our customers to develop materials and components, offering design assistance, finite element modeling, machining services, build-to-print components, and more.

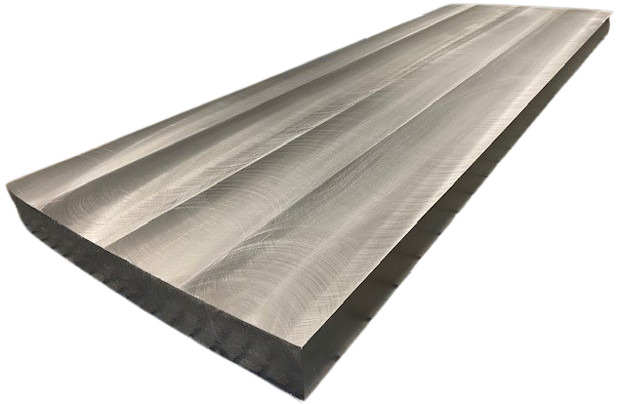

Elmet Technologies is able to supply pressed and sintered, as-forged, or fully-machined blanks, with our large sizes in rectangular and cylindrical shapes, fulfilling industry requirements. Given our highly experienced technical support and engineering team, we have extensive capabilities involving the customization of our molybdenum alloys to meet specific performance requirements.

With excellent strength and mechanical stability at high temperatures, our materials also provide high ductility and toughness. Each of these performance characteristics is critical for the production of precision parts in high-performance forging applications.

DATA SHEETS

Molybdenum (Mo) Powder Metallurgy (PM) Billet

Mo Alloy Arc-Cast (AC) Forging Billet

Mo Arc-Cast (AFB-30W) Forging Billet

TZM Powder Metallurgy (PM) Billet

TZM Arc-Cast (AC) Forging Billet

BROCHURES

The Elmet Technologies Advantage

- Precision Fabrication: advanced machining for complex parts

- Alloy Development: alloys engineered for extreme performance

- U.S.A. Manufacturing: high-quality, reliable, and secure supply chain

- Proven Performance: trusted in aerospace and defense applications

- Flexible Production: from prototyping to high-volume manufacturing

- ISO 9001 and AS9100: registered to top-quality management systems

- Responsive Technical Support: excellent customer service experience