TZM Forging Dies

Elmet Technologies is the leading manufacturer of TZM forging dies, using high-quality materials with outstanding performance properties. Our materials offer improved forging performance to assist in the creation of parts that require high strength and the ability to withstand high temperatures. Military, defense, and aerospace contractors rely on our unique refractory metals expertise, as well as our advanced powder metallurgy capabilities, to deliver mission-critical products of unmatched quality and enhanced reliability.

As the last and only 100% U.S.-owned-and-operated fully integrated manufacturer of TZM material, we provide the highest quality service and knowledge base for your forging purposes, with a process that allows us to meet precise performance requirements.

Our Capabilities and Key Processes

- Supply of pressed and sintered, as-forged, or fully machined blanks

- Quality systems and registrations include: AS9100, ISO9001, and ITAR

- Specialized capabilities with an exclusive vacuum arc-casting process

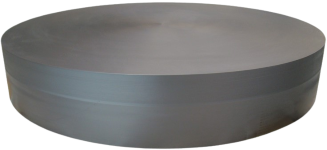

- Rectangular or cylindrical shapes available, capabilities with large sizes

- Experienced team of engineers and responsive customer support team

- Development of custom materials and components for forged products

- Custom alloys and TZM forging dies materials for project-specific needs

TZM Forging Dies: Materials and Specifications

Elmet Technologies’ TZM forging die material is consolidated by either the powder metallurgy process, or by our unique vacuum arc-casting process. The titanium and zirconium carbides increase strength and creep resistance at elevated temperatures. In addition, the use of TZM also enables higher service temperatures without the loss of strength in comparison to pure molybdenum (Mo).

CHARACTERISTICS

Minimum Density (based on 10.2 g/cc)

| Pressed and Sintered Billet | 94% |

| Forged Blank | > 99.5% |

Maximum Product Dimensions

| Pressed and Sintered Billet | 29 in. diameter (74 cm)/ 10,000 lb (4536 kg) |

| Forged Blank | 55 in. diameter (140 cm) |

We provide customization of alloys, a vacuum arc-casting process, finite element modeling, and large sizes in various shapes. Elmet Technologies ensures its TZM forging dies fulfill the performance and quality requirements of the aerospace and defense industries.

A Leading Provider of High-Performance Refractory Metals

Elmet Technologies stands at the forefront of the refractory metals industry, specializing in high-performance tungsten, molybdenum, niobium, and related alloys. We continue to invest in new manufacturing technologies and develop new materials. Our commitment to innovation allows us to meet the requirements of next generation applications and deliver the best value to our customers.