Molybdenum Alloy forging Dies

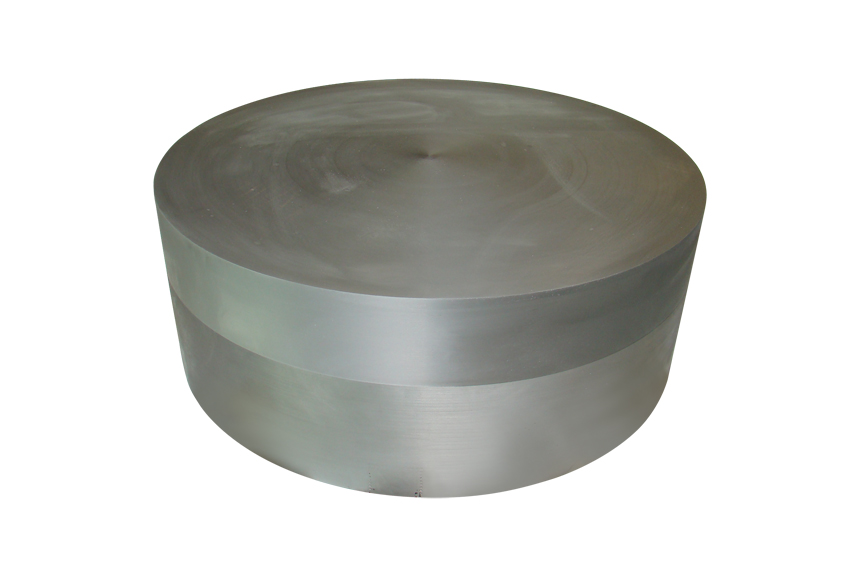

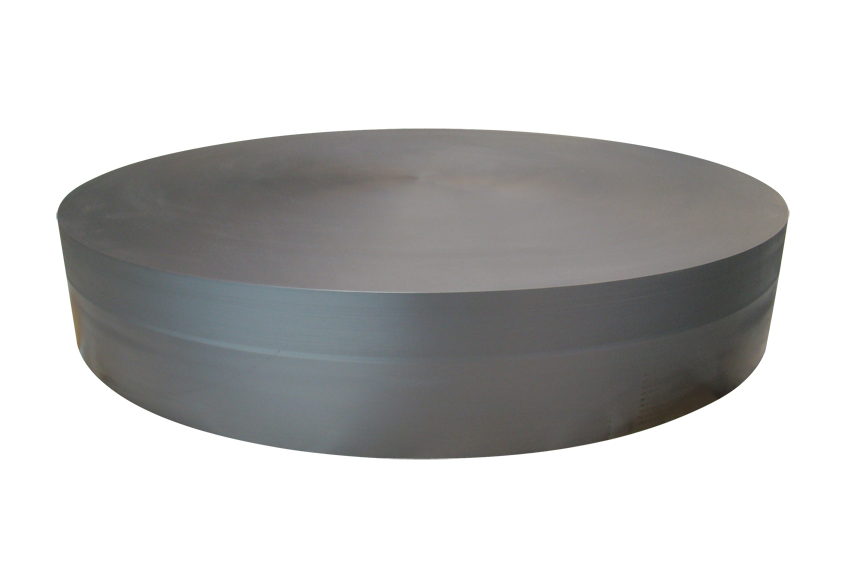

Elmet Technologies manufactures molybdenum alloy forging dies that ensure high performance, strength, and durability at extreme temperatures. Our customized superior die alloys result in higher-quality forged products. Some advantages include: high strength and high creep resistance at elevated temperatures, in addition to high recrystallization temperature due to the alloys implemented.

We offer finite element modeling and provide various large sizes of forging dies in multiple shapes with the ability to customize alloys. These molybdenum-based materials are made with exceptional metallurgical and processing expertise. The result is superior molybdenum alloy forging dies that enable further creation of some of the most technologically advanced products in the world.

Molybdenum Alloy Forging Dies Experts

The team at Elmet Technologies offers unmatched technical engineering and advanced manufacturing of refractory metals. Since 1929, customers have relied on our significant experience in the application of molybdenum alloys for new, innovative markets and demanding applications.

Mo Alloy

Molybdenum alloy forging dies are capable of withstanding intense heat and enormous compressive forces at the same time. These alloys have the ability to withstand high mechanical loads at high temperatures, also known as hot strength.

The Elmet Forging Dies Advantage

Suppliers of aircraft jet engines trust Elmet Technologies’ ability to deliver molybdenum alloy forging die solutions that meet precise and demanding requirements. Advantages include:

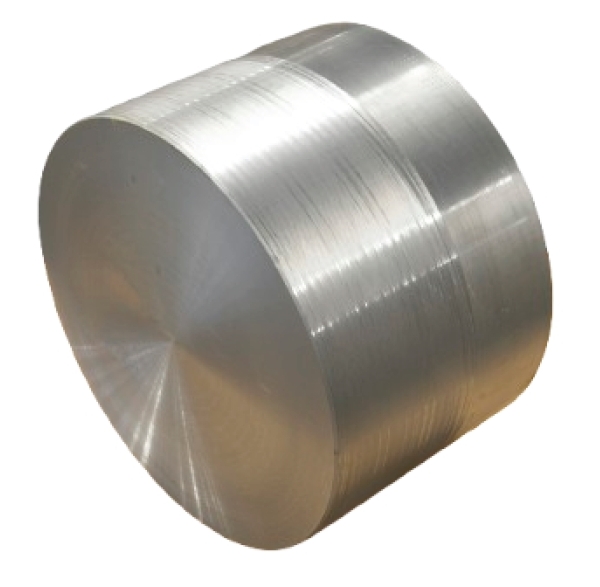

- Manufacture of pressed and sintered, as forged, or fully machined die blanks

- Customization of molybdenum (Mo) alloys to meet specific project requirements

- Extensive engineering support with finite element modeling of the forging process

- A wide variety of alloys, sizes, diameters, and shapes to fulfill custom project needs

- Development of specific components and build-to-print, design assistance services

Elmet Technologies is the only fully integrated U.S.-owned-and-operated manufacturer of molybdenum alloys.

Molybdenum Alloy Forging Dies Characteristics

Minimum Density (based on 10.2 g/cc)

| MHC | TZM | |

|---|---|---|

| Pressed & sintered billet | 94% | 94% |

| Forged blank | > 99.5% | > 99.5% |

Maximum Product Dimensions

| MHC | TZM | |

|---|---|---|

| Pressed & sintered billet | 29 in diameter (74 cm)/10,000 lb (4,536 kg) | 29 in diameter (74 cm)/10,000 lb (4,536 kg) |

| Forged blank | 55 in diameter (140 cm) | 55 in diameter (140 cm) |

For custom alloys, unique shapes, or sizes, contact our team of applications experts to discuss your specific forging die requirements.