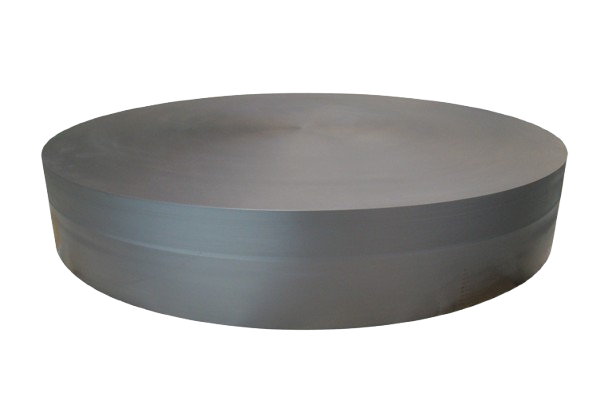

MHC Forging Dies

MHC forging dies provide excellent thermal conductivity, low thermal expansion, and significantly better strength at elevated temperatures. Elmet Technologies is a leading manufacturer of MHC material, an established Mo alloy containing hafnium carbide. Our unique powder metallurgy process enables high-quality die materials able to withstand extreme temperatures and stresses.

At Elmet Technologies, we apply exceptional manufacturing techniques and utilize some of the most unique materials in the world to deliver sophisticated refractory metal solutions for our customers. Our proven track-record combines advanced design, technical engineering, and precision manufacturing for superior performance and the utmost reliability, even in demanding environments.

Advanced MHC Forging Die Solutions

We work closely with our partners to understand their needs. In doing so, we develop advanced solutions to solve difficult technical challenges and provide manufactured products that exceed their requirements. Elmet Technologies continues to invest in manufacturing technologies and develops solutions for next-generation applications that utilize our refractory metal products and materials.

Materials and Specifications

Elmet Technologies’ MHC forging dies offer improved forging performance in the manufacture of diffusion bonding dies and isothermal forging dies, in addition to the associated components for the fabrication of low-and high-pressure turbine blades, vanes, discs, hubs, and rings. With extensive powder metallurgy techniques and advanced processing capabilities, we ensure the highest quality MHC material. Our applications knowledge enables us to customize refractory metals to meet precise requirements.

CHARACTERISTICS

Minimum Density (based on 10.2 g/cc)

| Pressed and Sintered Billet | 94% |

| Forged Blank | > 99.5% |

Maximum Product Dimensions

| Pressed and Sintered Billet | 29 in DIA (74 cm)/ 10,000 lbs. (4536 kg) |

| Forged Blank | 55 in DIA (140 cm) |

The MHC alloy is consolidated by an efficient powder metallurgy process. The advanced material properties of MHC yield several advantageous high-performance qualities, including: recrystallization temperature, thermal expansion, strength, and conductivity.

Your Partner for Specialty Alloys and Forging Die Solutions

Elmet Technologies specializes in manufacturing premium molybdenum (Mo) based alloys and high-performance forging die solutions. With a focus on precision, quality, and customer success, we supply robust materials tailored to meet stringent standards in highly demanding applications.

The Elmet Forging Dies Advantage

- Finite element modeling of the high-temperature forging process

- Capability to customize alloys to meet specific performance requirements

- Ability to manufacture pressed & sintered, as-forged, or fully machined blanks

- Offering exclusive vacuum arc-casting process capabilities for MHC forging dies

- Ability to partner with customers on build-to-print components and specifications

- Offering an accessible, dedicated, and responsive technical customer support team

- Wide range of custom sizes and large diameters in cylindrical and rectangular shapes

About Us

- Founded: 1929

- 100% U.S.-Based Manufacturing

- Locations: Maine, Michigan, Ohio

- Headquarters: Lewiston, ME, USA

- ISO9001, AS9100, ITAR Registered