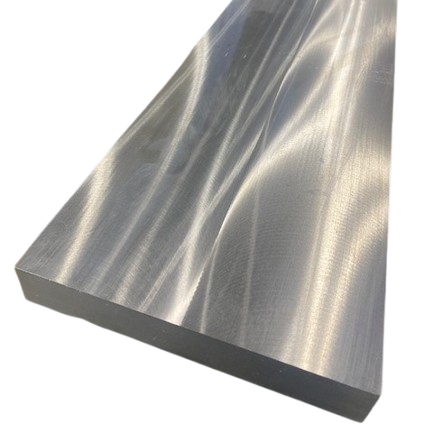

TZM Forging Blocks

Elmet Technologies produces TZM forging blocks using high performance refractory metal materials and advanced manufacturing techniques. Beginning with a highly specialized powder metallurgy process, our alloys exhibit superior performance characteristics, including higher strength and creep resistance at high temperature, making them ideally suited for demanding forging applications.

We employ a wide range of manufacturing techniques with high levels of precision to meet your requirements and suit even the most exacting of specifications. Our team combines cutting-edge technology with expert craftsmanship to deliver consistently exceptional results, ensuring quality and reliability at every stage of production. Elmet Technologies provides solutions with performance in mind.

Your Trusted Source for TZM Alloys

Since 1929, Elmet Technologies has been a trusted source for refractory metals. We offer an exceptional customer experience, high quality materials, and unmatched precision. Our TZM forging blocks meet the highest industry standards, providing superior strength and resistance to wear.

TZM Forging Blocks: Our Advantages

- Versatility. We offer pressed and sintered, as-forged, or fully machined block options

- Engineering. Finite element modeling (FEM) of the high temperature forging process

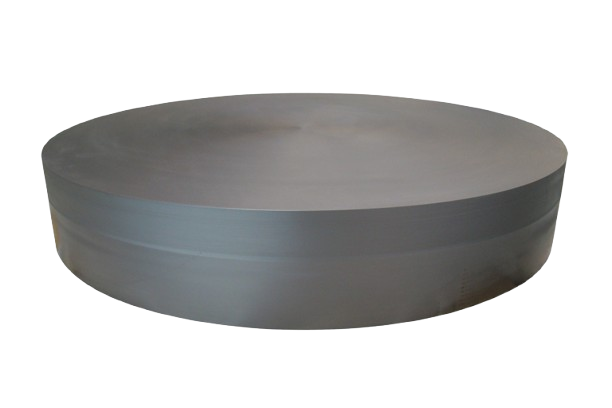

- Customization. Various shapes and large diameter sizes to meet custom requirements

- Materials Knowledge. Technical engineering support for molybdenum, MHC, and TZM

- Customer Focused. An emphasis on customer success with extensive technical support

Why TZM?

- Extraordinary strength

- Increased creep resistance

- Enhanced thermal conductivity

TZM Forging Blocks: Material Specifications

Elmet Technologies’ advanced TZM (Titanium-Zirconium-Molybdenum) forging blocks are manufactured using either our powder metallurgy process or a unique vacuum arc-casting process. When combined, Molybdenum (Mo), Titanium (Ti) and Zirconium (Zr) carbides are capable of increasing creep resistance and strength at higher temperatures. Characteristics for our TZM alloys include:

Min. Density (based on 10.2 g/cc)

| Pressed and Sintered Billet | 94% |

| Forged Blank | > 99.5% |

Max. Product Dimensions

| Pressed and Sintered Billet | 29 inch diameter (74 centimeters)/ 10,000 lbs. (4536 kg) |

| Forged Blank | 55 inch diameter (140 centimeters) |

TZM Forging Solutions for Aerospace

Elmet Technologies is revolutionizing aerospace manufacturing with its TZM forging solutions. We meticulously engineer our cutting-edge alloys for superior performance. These advanced materials enable precision and durability for critical components such as turbine blades, vanes, discs, hubs, and rings. Our state-of-the-art processing techniques ensure we meet the most stringent of requirements.