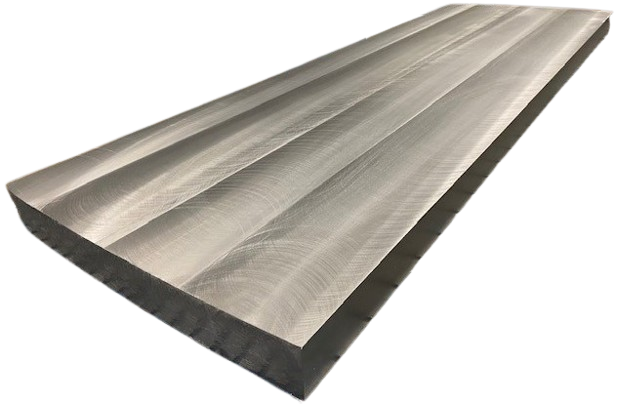

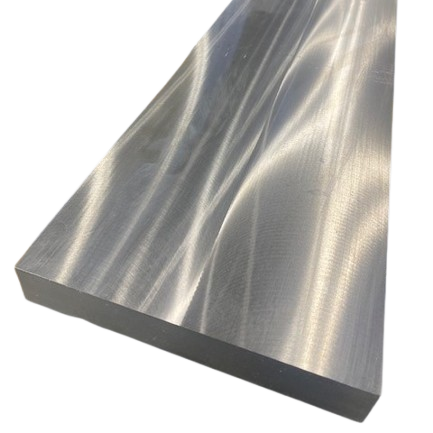

Molybdenum Alloy forging Blocks

Elmet Technologies produces molybdenum alloy forging blocks with enhanced high-performance characteristics and metallurgical properties. Beginning with our unique powder metallurgy method, our engineering process yields forging block solutions with exceptional thermal stability, superior wear resistance, and optimized microstructure to withstand extreme mechanical stresses.

Optimized for the high-temperature environments of metalworking applications, our specialty molybdenum alloy materials and precision engineering solutions deliver mechanical integrity, enhanced hardenability, and superior creep resistance. Elmet continues to leverage its expertise in powder metallurgy and refractory metals, enabling next generation advancements in material forging.

High-Performance Molybdenum Alloys

Our high-performance molybdenum alloys are engineered and manufactured to meet the requirements of demanding applications. Whether you require Titanium-Zirconium-Molybdenum (TZM), Molybdenum-Hafnium-Carbide (MHC), or other molybdenum (Mo) alloys for your forging application, our materials are ideal for high-temperature environments and precision manufacturing.

Molybdenum Alloy Forging Blocks: Specifications

Maximum Product Dimensions

| MHC Alloy | TZM Alloy | |

|---|---|---|

| Pressed and Sintered Billet | 29 in. diameter (74 cm)/10,000 lb. 4536 kg) | 29 in. diameter (74 cm)/10,000 lb. 4536 kg) |

| Forged Blank | 55 in. diameter (140 cm) | 55 in. diameter (140 cm) |

Minimum Density (based on 10.2 g/cc)

| MHC Alloy | TZM Alloy | |

|---|---|---|

| Pressed and Sintered Billet | 94% | 94% |

| Forged Blank | > 99.5% | > 99.5% |

We engineer and manufacture all molybdenum alloy forging blocks to meet the highest industry standards, delivering exceptional performance in high-temperature and high-stress applications. Our specialty materials include Molybdenum-Hafnium-Carbide (MHC), which offers superior thermal stability and wear resistance, and Titanium-Zirconium-Molybdenum (TZM), known for its remarkable strength and corrosion resistance. Through precision manufacturing processes and strict quality procedures, our products meet tight tolerances and consistent material properties, with custom solutions available to meet your specifications.

Elmet: Precision and Performance

At Elmet, we combine our expertise in powder metallurgy with cutting-edge manufacturing technology to deliver molybdenum alloy forging blocks that excel in the most demanding environments. Partnering with Elmet Technologies offers the following advantages:

- Production of fully-machined, pressed and sintered, as-forged, or custom blanks

- Ability to tailor specific alloy compositions to meet project-specific requirements

- New component development, build-to-print design and manufacturing services

- Extensive range of alloy systems and geometric configurations to fit unique needs

- Comprehensive engineering and simulation, including FEA and further optimization

Elmet Technologies is the leading U.S.-owned-and-operated, fully integrated manufacturer of molybdenum alloys.

Next-Generation Forging Solutions

Elmet Technologies molybdenum alloy forging blocks are becoming increasingly relied upon in advanced manufacturing processes, especially in industries requiring both structural integrity and resistance to extreme operational conditions. Our next-generation solutions enable the fabrication of mission-critical aerospace components and other high-stress parts for many demanding applications.