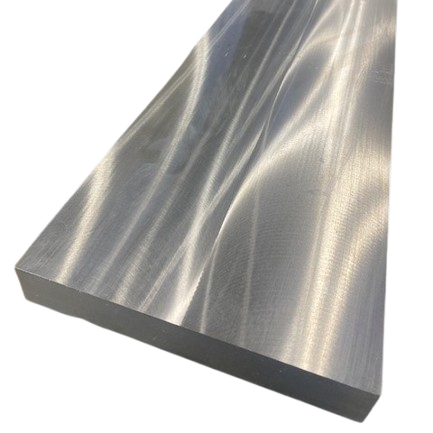

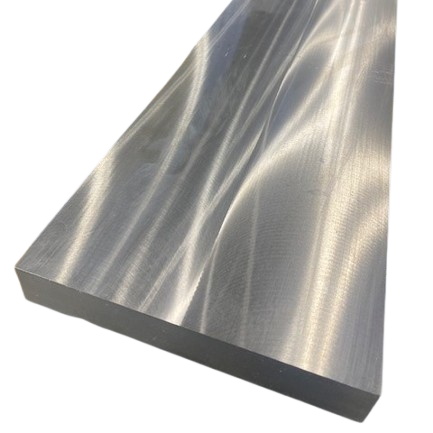

MHC Forging Blocks

Elmet Technologies manufactures its premium MHC forging blocks by utilizing advanced materials and state-of-the-art processing techniques. Our approach begins with the powder metallurgy process to form unique alloys that offer exceptional strength, creep resistance, and durability at extremely high temperatures. We have the ability to customize materials to fit your exact requirements.

Engineered for peak performance in demanding applications, our materials and solutions set the standard for high-temperature strength, improved hardenability, and high creep resistance. Elmet Technologies couples its expertise in powder metallurgy with extensive precision manufacturing capabilities, delivering forging materials and solutions for various critical industries of the future.

Global Leader in MHC Forging Solutions

Elmet Technologies has decades of experience in the design, engineering, and manufacturing of high-performance MHC forging solutions, including: dies, blanks, blocks, billets, and more. Our powder metallurgy expertise and highly specialized processes enable us to deliver custom forging solutions for demanding applications, along with extensive technical and engineering support.

The Elmet Technologies Advantage

- Supplying industry-compliant large-format cylindrical and rectangular components for high-performance applications.

- Offering precision-engineered blanks in pressed & sintered, near-net forged, or fully machined forms to meet diverse manufacturing needs.

- TZM and MHC alloys with material customization to exact performance specifications, ensuring optimal functionality for advanced manufacturing applications.

- A team of experts with deep technical knowledge and hands-on industry experience, backed by our customer support specialists and a dedicated engineering team.

- Decades of expertise in supplying isothermal die components, delivering performance and extreme reliability for manufacturing applications that require the utmost precision.

Experts in MHC Forging Solutions

MHC Forging Blocks: Specifications and characteristics

Maximum Product Dimensions

| Pressed and Sintered Billet | 29 in. diameter (74 cm)/10,000 lb. 4536 kg) |

| Forged Blank | 55 in. diameter (140 cm) |

Minimum Density (based on 10.2 g/cc)

| Pressed and Sintered Billet | 94% |

| Forged Blank | > 99.5% |

Elmet Technologies collaborates closely with its customers to engineer project-specific solutions, including precision build-to-print components. We offer extensive knowledge and capabilities with molybdenum (Mo) alloy machining. In addition, our advanced design assistance can optimize material performance, manufacturability, and efficiency, even for the most demanding of applications.

Innovative MHC Forging Solutions

Our innovative, high-performance molybdenum alloys are compatible with a wide range of manufacturing techniques. We offer a unique fabrication approach that ensures MHC forging blocks can be produced with high levels of precision to suit a range of extremely demanding applications.