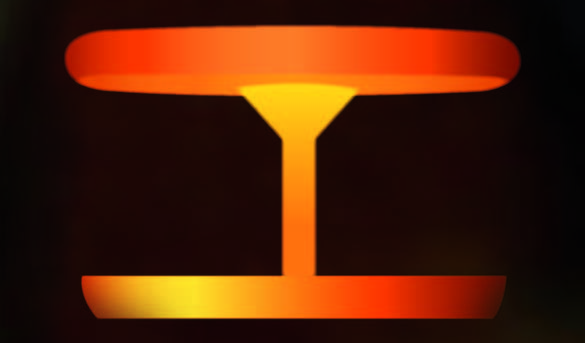

MHC Forging Blanks

Elmet Technologies manufactures high-performance MHC forging blanks with low thermal expansion and excellent thermal conductivity. We supply pressed and sintered, as-forged, or fully machined blanks, utilizing our innovative alloy materials. Our advanced materials help to expand the possibilities of hot metalworking processes and enable the creation of new technologies.

As the sole U.S.-owned-and-operated manufacturer with a fully integrated process for refractory metals, Elmet Technologies stands ready to provide materials for high-tech industries that demand high performance, high quality, and extremely precise manufacturing.

MHC: Molybdenum-Hafnium Carbide

Engineered for peak performance, MHC is a cutting-edge molybdenum-based alloy, reinforced with hafnium carbide. Developed using a state-of-the-art powder metallurgy process, it offers superior strength and extreme thermal stability, providing enhanced performance for forging applications.

MHC Forging Blanks: Specifications

Minimum Density (based on 10.2 g/cc)

| Forged Blank | > 99.5% |

Maximum Product Dimensions

| Forged Blank | 55 in. (140 cm) DIA |

For more information or custom material properties, contact Elmet to discuss your needs.

ABOUT mhc ALLOY

- Molybdenum-Hafnium-Carbide

- High strength

- Low thermal expansion

- High thermal conductivity

- High recrystallization temperature

The Elmet Technologies Advantage

Elmet Technologies is quality-driven, customer-focused, and committed to innovation through research and development. Advantages of partnering with Elmet include:

- Unique focus on critical domestic applications, including defense and aerospace

- Extensive line of capabilities with pressing, sintering, forging, machining, and more

- Rigorous powder metallurgy quality control process results in high-quality material

- Development of custom components and build-to-print, design assistance services

- High production capacity across three USA locations, over 500,000 square feet total

Elmet Technologies is the only fully integrated producer of MHC forging blanks that is U.S.-owned and operated.

Refractory Metals for Forging Applications

Our refractory metals offer high corrosion resistance, high density, and retain superior mechanical strength at high temperatures. These unique features of refractory metals prove as advantageous in various challenging applications that face demanding performance requirements. In forging processes and environments, molybdenum-based alloys serve as an efficient solution.

MHC Alloy: Molybdenum-Hafnium-Carbide, has excellent thermal conductivity, as well as low thermal expansion. MHC forging blanks resist corrosion and improve the dimensional uniformity of a product. In addition, MHC has the potential to extend the life of the die.

Other Materials and Alloys: Elmet Technologies also manufactures TZM and other molybdenum materials and components. Our extensive powder metallurgy capabilities allow us to custom develop alloys that meet the specific requirements of our customers.