Capabilities

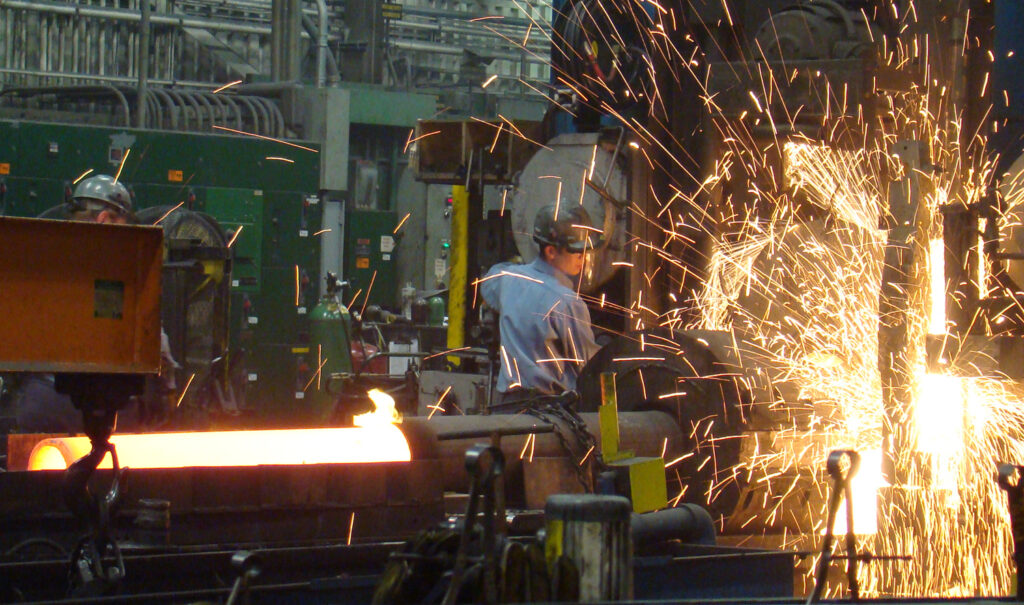

Elmet Technologies leverages fully-integrated production capabilities to ensure precision, material performance, and quality control. Our manufacturing process involves advanced powder metallurgy methods and specialized manufacturing techniques that transform our refractory metal materials into finished products for our customers. We ensure consistency from powder to product.

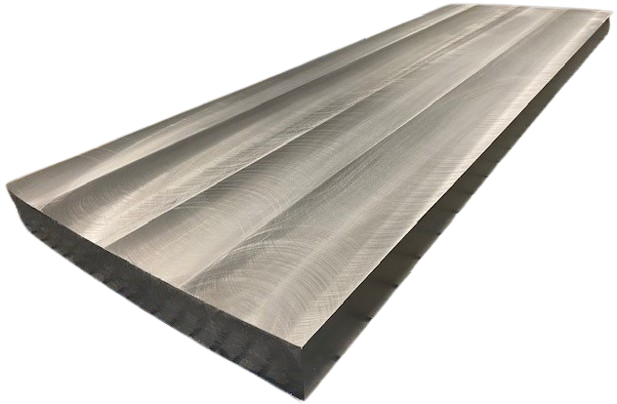

Key production capabilities include: alloy development, rotary forging, extrusion, hot and cold rolling, additive manufacturing, sintering, swaging, advanced machining, and more. Elmet has three U.S. manufacturing sites that complement one another. Each has its own dedicated center of excellence. Our products and solutions push far beyond the performance limits of ordinary metals.

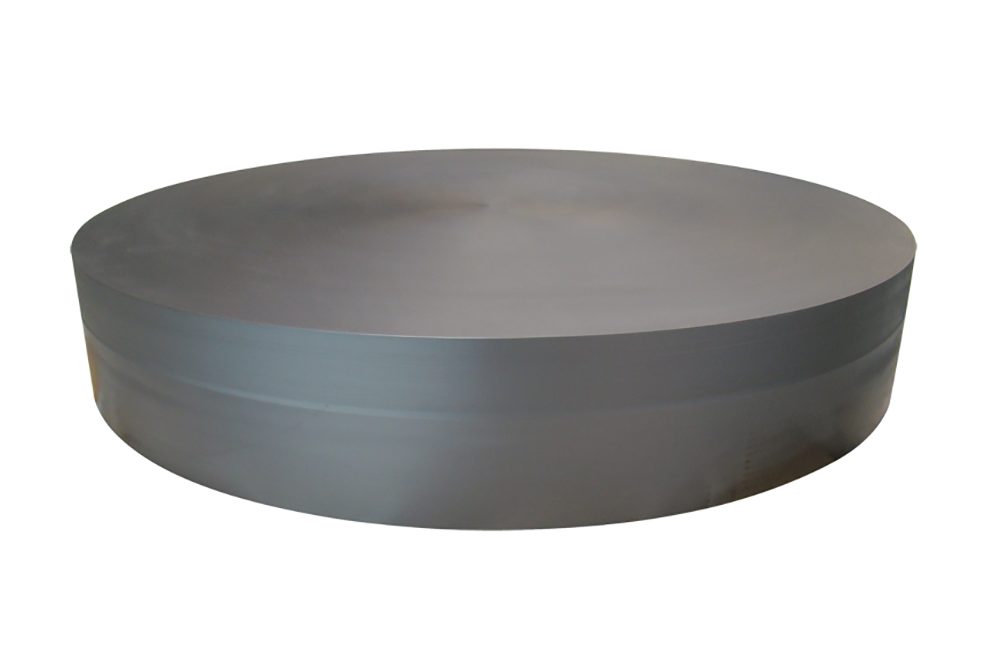

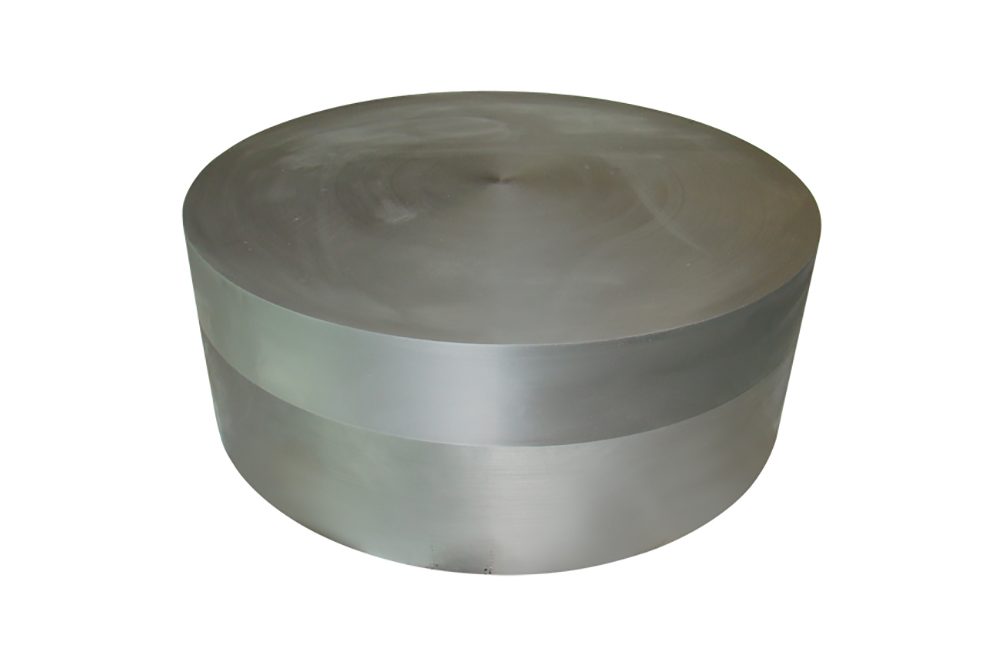

Isothermal

Forging

In isothermal forging, dies are heated to the same temperature as the forged part. It is conducted on superalloys, in a vacuum or a highly-controlled atmosphere to prevent oxidation.

Advanced

Capabilities

Elmet Technologies offers extensive application knowledge, experience, capabilities, and advanced technological processes that enable us to customize our alloys to meet precise requirements.

Diffusion

Bonding

In diffusion bonding, a solid-state welding technique is utilized, typically implemented by applying high pressure, along with necessarily high temperature, to the materials to be welded.

End-to-end manufacturing capabilities

Starting with powder metallurgy, we control every step of the manufacturing process: from blending and alloying, pressing and sintering, to machining and fabrication. Our unparalleled product line covers several forms, from high-purity tungsten and molybdenum powders, to finished mill products and components. Our full process capabilities ensure consistent quality and reliable performance.

The Elmet Technologies Advantage

- Forging dies available in large, customizable shapes and sizes

- Several decades of manufacturing isothermal die components

- TZM alloy solutions for high strength at elevated temperatures

- MHC alloy solutions for excellent thermal conductivity and strength

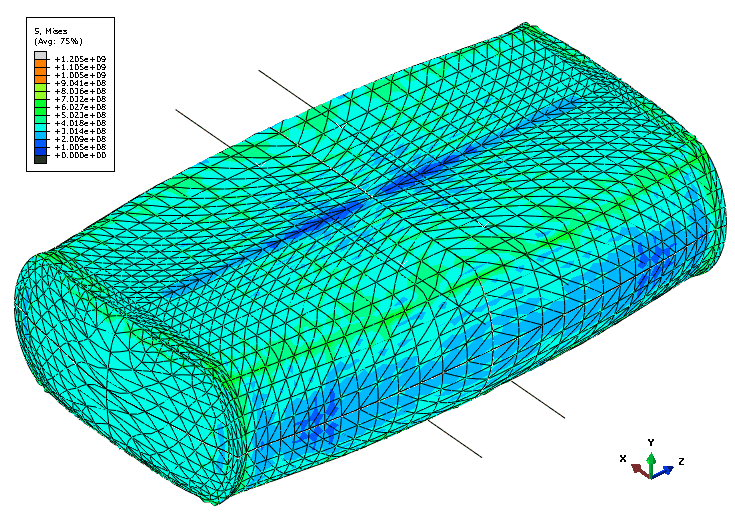

- Our precision forging solutions improve metal flow and part accuracy

- Materials exhibiting excellent dimensional stability under high pressure

- Offering customization of materials or specific alloys to fit requirements

The Experts in Forging Die Solutions

Aerospace engine manufacturers rely on Elmet Technologies for our deep expertise and longstanding ability to tailor high-performance refractory metal solutions to exacting specifications. With decades of hands-on experience and advanced in-house capabilities, we deliver materials engineered to perform in the most demanding environments. Our customer-centric and quality-driven approach offers consistent results, technical partnership, and precise manufacturing.