Isothermal Forging Dies

Elmet Technologies specializes in engineering and manufacturing isothermal forging dies with advanced performance characteristics. Our extensive material capabilities includes the customization of alloys to improve the overall forging process, therefore resulting in higher quality end products. We offer complete control over material integrity, quality, and performance.

Materials include molybdenum alloys, such as Titanium-Zirconium-Molybdenum (TZM), and Molybdenum Hafnium Carbide (MHC). We also produce other custom materials optimized for isothermal forging conditions. Our team of expert metallurgists and engineers work closely with each customer to select materials and tailor them to specific applications, forging geometries, and requirements.

What Is Isothermal Forging?

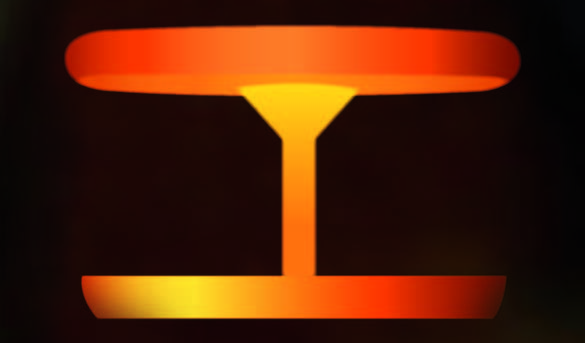

Isothermal forging is a precision forming process performed at elevated temperatures, where both the die and workpiece are held at nearly constant temperature during deformation. This controlled environment minimizes thermal gradients, allowing for superior grain flow, tighter tolerances, and improved material properties. Isothermal forging is especially critical when metalworking with difficult-to-form materials, such as titanium, nickel-based superalloys, and refractory metals.

Elmet Forging Die Capabilities

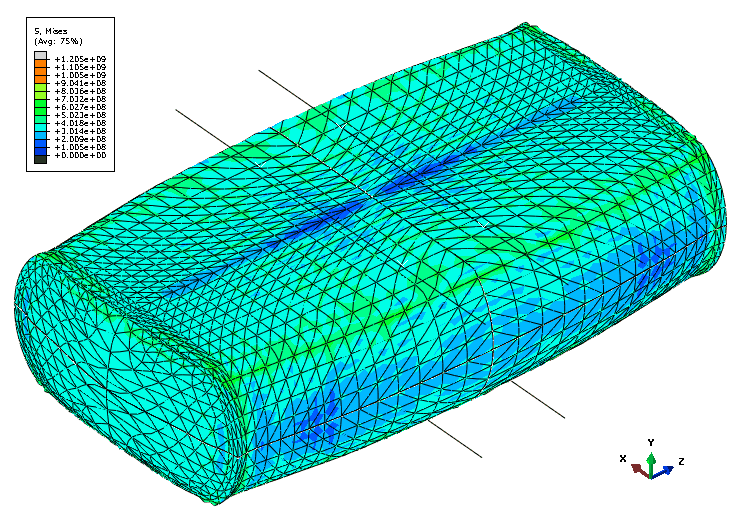

- Engineering: finite element modeling (FEM) of the forging process

- Technical Support: highly experienced technical engineering team

- Various Sizes: large format sizes in cylindrical or rectangular shapes

- Proven Solutions: decades of supplying isothermal forging products

- Manufacturing: built-to-print components to meet your requirements

- Versatility: supply as pressed & sintered, fully machined, or as-forged

- Customization: ability to customize TZM, MHC, and molybdenum alloys

Our High-Performance Forging materials

At Elmet Technologies, we engineer isothermal forging dies using advanced refractory metal materials that deliver unmatched thermal stability, precision, and longevity under extreme conditions. With deep expertise in molybdenum alloys, including TZM, MHC, and others, our dies are purpose-built to support critical aerospace and high-temperature applications where performance is key.

Our fully-integrated manufacturing process gives us full control over material quality, grain structure, and mechanical properties. This ensures each die meets exact performance standards and project requirements. From concept to final machining, we partner with customers to deliver tailored solutions that extend die life and improve forging quality in every cycle, leading to better end products.

Backed by nearly a century of refractory metals expertise, our isothermal forging dies consistently perform in the most thermally aggressive environments without deformation or failure. Our deep expertise with high-performance materials allows us to engineer dies with application-specific quality requirements. We have the ability to tailor our materials and products to fit your project needs.

Your Partner for Isothermal Forging

As the last and only 100% U.S.-owned-and-operated, fully integrated manufacturer of tungsten and molybdenum solutions, Elmet Technologies is your partner for precision isothermal forging solutions. We consistently deliver tooling that performs under the most demanding conditions, and our team works closely with you from concept though production to ensure consistency, reliability, and performance. Elmet is committed to being a partner through the entire manufacturing process.