Applications

Elmet Technologies designs, engineers, and manufactures its forging dies for extreme performance in demanding environments and applications. Our expertise in molybdenum and high-performance alloys enables us to tailor our forging die solutions specific to the environment, whether aerospace, defense, industrial, or other. We deliver unmatched quality and durability for your forging die needs.

As critical tools in metal forming processes, shaping metal into precise geometries under high pressure and temperature is no easy task. Our several die forms support diverse forging operations, each tailored for specific manufacturing needs and material properties. From billets to blanks, Elmet Technologies delivers forging die solutions optimized for your application requirements.

High-Performance Applications Experts

Aerospace engine manufacturers rely on Elmet Technologies for specialized expertise in high-performance applications. Our in-depth knowledge, advanced processes, and mastery of refractory metal alloys allow us to engineer custom forging dies and materials that meet the rigorous demands of aerospace applications. Our advanced applications team is readily available to discuss your needs.

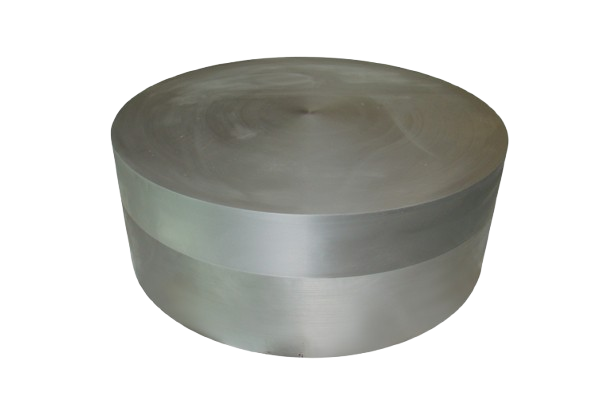

Diffusion

Bonding Dies

Diffusion bonding involves a solid-state welding technique. Typically, high pressure and high temperature are applied to the materials being welded.

About Elmet Technologies

Our specialists help develop custom components and design alloy materials to meet unique performance needs for the aerospace and defense industries.

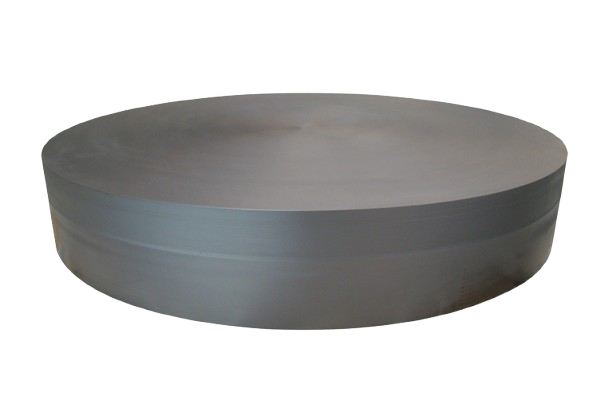

Isothermal

Forging Dies

Isothermal forging involves heating dies to the same temperature as the forged part itself. Typically, this happens in a highly controlled or vacuum type atmosphere.

Fully-Integrated USA Manufacturing

Our fully-integrated USA manufacturing delivers exceptional quality and consistency for forging dies used across demanding applications. Our team of experts ensures tighter tolerances, faster lead times, and full traceability for an unmatched customer experience. We customize forging dies to meet complex geometries, high-temperature requirements, and extreme mechanical stresses.