Titanium Zirconium Molybdenum Alloy

Titanium Zirconium Molybdenum (TZM) Alloy is a molybdenum-based alloy with added titanium and zirconium for enhanced properties. This high-performance alloy is engineered to deliver superior strength, stability, and creep resistance at elevated temperatures. TZM offers great thermal conductivity and low thermal expansion. As one of the most often used molybdenum-based alloys, it is ideal for demanding applications in aerospace, defense, electronics, and high-temperature industrial environments.

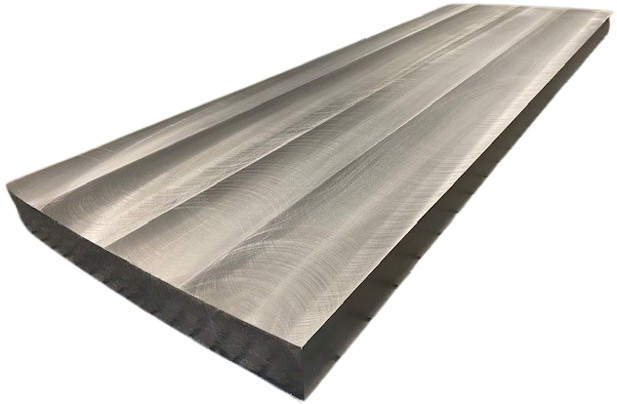

Offering extraordinary strength at the isothermal forging temperature, TZM Alloy is an ideal material for forging dies and related components. It also improves grain structure, significantly boosting mechanical performance under heat and stress. The strength and creep resistance at extremely high forging temperatures is strengthened by the titanium and zirconium carbides in this alloy, enabling the use of elevated materials without the loss of strength when pure molybdenum is utilized in the forging process.

TZM: Titanium, Zirconium, Molybdenum

TZM alloy is comprised of Titanium, Zirconium, and Molybdenum. It contains 0.50% titanium (Ti), 0.08% zirconium (Zr), with the balance molybdenum (Mo). Uniquely, the titanium and zirconium carbides increase strength and creep resistance at elevated temperatures. The use of TZM also enables higher service temperatures without loss of strength in comparison to pure molybdenum.

TZM: Material Specifications

Minimum Density (based on 10.2 g/cc)

Maximum Product Dimensions

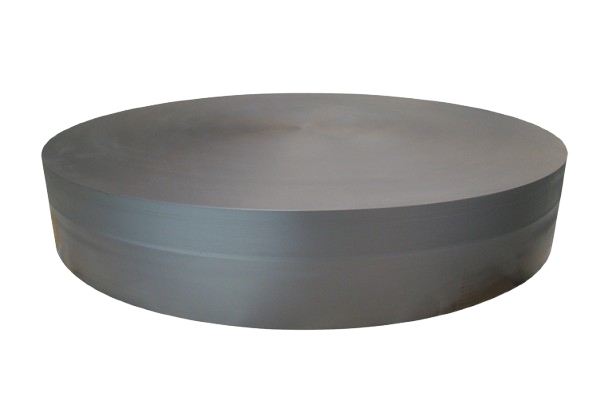

| Pressed and Sintered Billet | 29 in. (74 cm) DIA /10,000 lbs. (4,536 kg) |

| Forged Blank | 55 in. (140 cm) DIA |

For more information, contact Elmet Technologies to discuss your application requirements.

ABOUT TZM ALLOY

- Titanium-Zirconium-Molybdenum

- Good thermal conductivity

- Higher strength than pure Mo

- Performs in extreme conditions

- Higher creep resistance than Mo

TZM Alloy: Common Applications

Due to its superior mechanical and thermal characteristics, TZM Alloy supports several critical applications. This includes rocket nozzles and propulsion components, high-temperature tooling and dies, industrial furnace components, X-ray and radiation shielding, and semiconductor equipment. Its unique combination of high-temperature strength, thermal stability, and wear resistance makes it a critical material for several advanced and high-tech industries that require the utmost precision.

Other TZM Products Manufactured by Elmet Technologies

In addition to forging dies and related components, Elmet Technologies also manufactures a wide range of TZM products in various forms, including: rod, sheet, plate, and more. Our metallurgical and processing expertise ensures the highest quality TZM, MHC, and molybdenum alloy forging materials.