Forging Billets

Elmet Technologies is the leading U.S. manufacturer of forging billets with advanced performance characteristics for demanding applications. Our specialty materials and refractory metal alloy solutions offer an unparalleled strength to withstand high mechanical loads, even at extremely elevated temperatures. We collaborate with each customer to manufacture to their exact requirements.

As the last and only U.S.-owned-and-operated, fully integrated manufacturer of molybdenum and its related alloys, partnering with Elmet Technologies for your forging needs enables access to industry-leading technical expertise with extensive customer support. With a wide range of materials, geometries, and sizes, our forging solutions enable the creation of high-quality finished products.

Forging Billets With Superior Quality

We specialize in the design, engineer, and manufacture of forging billets with unmatched durability and precision. Our process centers around a unique powder metallurgy process. This process ensures that every product is made from high-quality material, able to meet the highest industry standards.

Characteristics and specifications

Maximum Product Dimensions

| Molybdenum-Hafnium-Carbide (MHC) Alloy | Titanium-Zirconium-Molybdenum (TZM) Alloy | |

|---|---|---|

| Forged Blank | 55 in. diameter (140 cm) | 55 in. diameter (140 cm) |

| Pressed and Sintered Billet | 29 in. diameter (74 cm)/10,000 lb. 4536 kg) | 29 in. diameter (74 cm)/10,000 lb. 4536 kg) |

Minimum Density (based on 10.2 g/cc)

| Molybdenum-Hafnium-Carbide (MHC) Alloy | Titanium-Zirconium-Molybdenum (TZM) Alloy | |

|---|---|---|

| Pressed and Sintered Billet | 94% | 94% |

| Forged Blank | > 99.5% | > 99.5% |

Elmet Technologies’ advanced Mo-based alloys enhance forging efficiency in the creation of isothermal and diffusion bonding dies, along with related components used in manufacturing both low- and high-pressure turbine blades, vanes, discs, hubs, and rings. With our deep expertise in powder metallurgy and refractory metal manufacturing, we fabricate forging billets of the highest quality.

DATA SHEETS

BROCHURES

Capabilities

- Superior quality molybdenum-based alloys (MHC and TZM) with high hot strength

- Comprehensive options for pressed & sintered, as-forged, or fully machined blanks

- Large-format rectangular and cylindrical shapes that meet latest industry standards

- High manufacturing capacity with state-of-the-art metallurgy processing equipment

- Advanced engineering methods for the fabrication of high-performance components

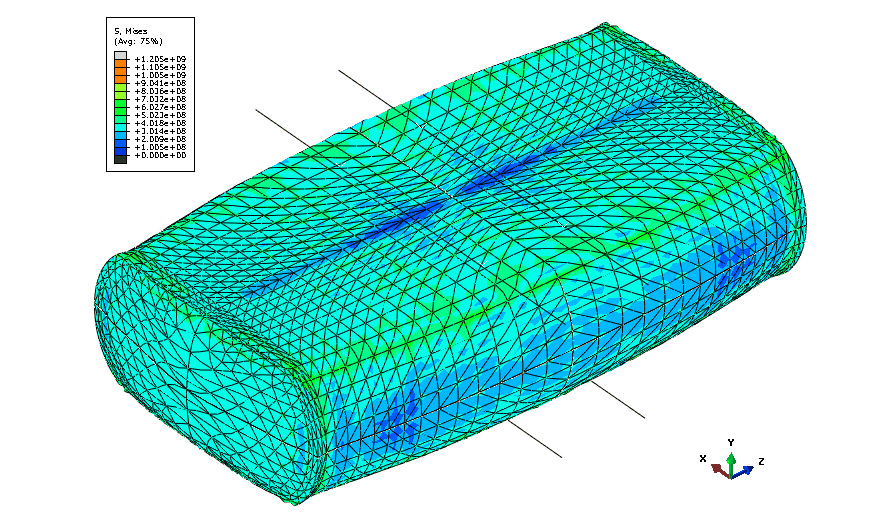

- Offering unique finite element modeling (FEM) of the high temperature forging process

- Customizing molybdenum alloys, TZM and MHC, to meet specific project requirements

The Advantages of Elmet Materials

Elmet Technologies understands advanced manufacturing processes, providing the industry with the highest standards for forging billets with its high-performance molybdenum alloys.

- Ability to survive high temperatures and extreme stresses

- Excellent thermal conductivity and low thermal expansion

- Saving processing costs with better materials that enable new technologies

- Extend the life of the die with ability to improve product dimensional uniformity

- Extreme resistance to erosion, friction, and wear, even in extreme environments