MHC Forging Billets

MHC forging billets are precision-engineered to deliver unmatched strength, thermal stability, and wear resistance for various applications. Elmet Technologies provides the industry with the highest standards for efficient forging with its advanced alloy materials. We provide extensive metallurgy and engineering expertise to quickly and accurately meet your project requirements.

As the last and only U.S.-owned-and-operated, fully-integrated manufacturer of high-performance molybdenum (Mo) materials and components, our end-to-end process enables a partnership that focuses on providing outstanding technical customer support.

A Leader in MHC Forging Billets for Demanding Applications

Elmet Technologies works closely with each customer to support material development, design collaboration, precision machining, and manufacturing services for our MHC forging billets.

MHC: Material Characteristics

Max. Product Dimensions

| Pressed & sintered billet | 55 in. (140 cm) diameter |

Min. Density (based on 10.2 g/cc)

| Pressed & sintered billet | 94% |

Custom material properties and additional specifications are provided upon request.

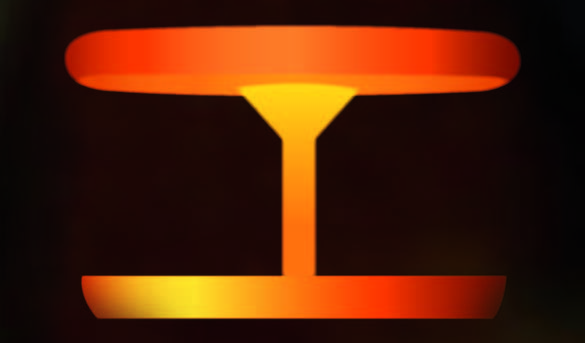

ABOUT MHC ALLOY

- Molybdenum-Hafnium-Carbide

- Used in aerospace applications

- Excellent strength and durability

- Proven resistance to extreme heat

- Exceptional thermal stability and creep resistance

Innovative MHC Engineering Capabilities

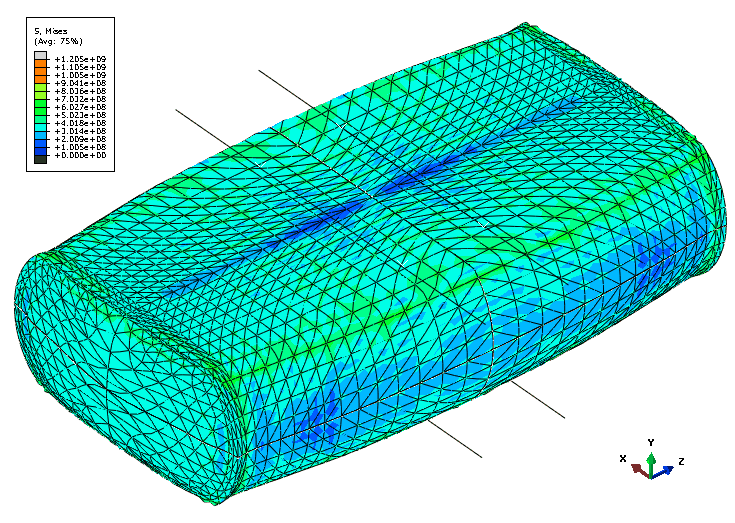

Our innovative capabilities with MHC forging billets includes finite element modeling (FEM) of the high temperature process and the ability to create custom alloys for specific project requirements. In addition, we have customized die alloys to improve the forging and diffusion bonding process, resulting in high-quality products. Elmet also supplies large sizes with various shapes available.

Your Partner for High-Performance MHC Forging Billets

Elmet Technologies is your partner for high-performance forging billets, optimizing each solution directly to your specific application or project requirement. Through our controlled powder metallurgy process, precise alloying, and refined thermal treatments, we deliver high-quality billets with superior microstructural uniformity and consistent performance characteristics.

Whether your application is aerospace, defense, energy, industrial, or other, our MHC forging billets are designed and engineered to perform under pressure. Backed by our advanced metallurgy expertise, strict quality control processes, and the latest in manufacturing technology, we deliver products that ensure superior performance, structural integrity, and long-term reliability.

Why Partner With Us?

- 100% Domestic Manufacturing: We support and contribute to critical segments of the U.S. Industrial Base.

- Responsive, Technical Partnership: We work with your teams to meet engineering and delivery requirements.

- Industry-Leading Quality Standards: Every billet is manufactured to meet rigorous industry and client-specific standards.

- Scalable Production Capacity: Whether prototype or full-scale production, we deliver what you need – on time, every time.