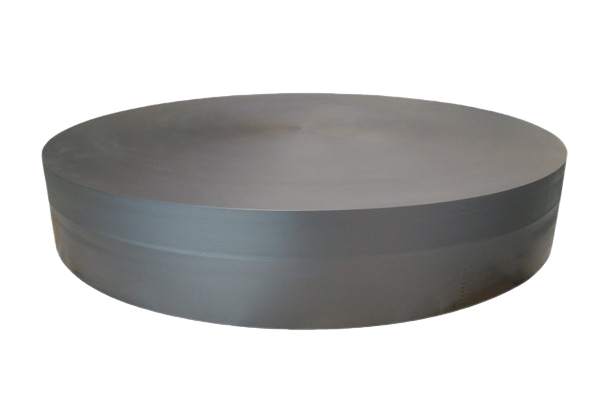

TZM Forging Blanks

TZM forging blanks are engineered and manufactured for superior strength, heat resistance, and extreme durability in demanding conditions. Elmet Technologies offers high-performance alloy materials with exceptional mechanical properties, enhanced wear resistance, and thermal stability for high-stress environments. We can also customize our materials to meet your requirements.

We offer an extensive, fully integrated powder metallurgy process with exceptional quality control, which not only ensures the highest quality material, but also further enables us to customize our refractory metal alloys to meet the most exact of project requirements.

A Global Leader In TZM Forging Blanks

Elmet Technologies is a fully integrated manufacturer of high-performance TZM forging blanks. Our expertise extends from high purity metal powder production through precision forming, fabrication, and machining capabilities. We offer a unique customer experience through a friendly customer service team, accessible technical engineering support, and industry-leading delivery times.

TZM: Materials & Specifications

CHARACTERISTICS

Minimum Density (based on 10.2 g/cc)

| Forged blank | > 99.5% |

Maximum Product Dimensions

| Forged blank | 55 in. (140 cm) diameter |

For customized solutions, contact Elmet Technologies to discuss your requirements.

ABOUT TZM ALLOY

- Titanium-Zirconium-Molybdenum

- 0.50 Ti, 0.08 Zr, Bal Mo

- Increased strength

- Improved creep resistance at elevated temperatures

- Enables higher service temperatures without the loss of strength, in comparison to pure molybdenum

Enhanced TZM Alloys for Advanced Forging Applications

Elmet Technologies’ advanced molybdenum alloys, such as MHC and TZM, enhance forging performance for diffusion bonding and isothermal forging dies, as well as related components used in manufacturing low-pressure and high-pressure turbine blades, vanes, discs, hubs, and rings. With our metallurgical expertise and ultra-precise manufacturing, we deliver the highest quality materials.

TZM Alloy: Titanium-Zirconium-Molybdenum, is consolidated by the powder metallurgy process or via our unique vacuum arc-casting process. Titanium (Ti) and zirconium (Zr) carbides increase both creep resistance and strength at elevated temperatures. Additionally, using TZM alloy allows higher service temperatures without loss of strength when compared to pure molybdenum (Mo).

Custom Alloys and Materials: We regularly partner with customers to develop custom alloys, materials, and components. Elmet offers build-to-print capabilities, as well as design assistance for machining molybdenum alloy products, materials, and solutions.

Your Partner in TZM Forging Blanks

Elmet Technologies is your partner in the manufacture of TZM forging blanks. Our advanced capabilities includes an extensive range of refractory metal and powder metallurgy products and services, including: alloy development, extrusion, advanced machining, rotary forging, and more.